Why Berntsen Metal Survey Caps Set the Standard

Berntsen marker at Machu Picchu

Quality Specifications That Outperform the Rest

At Berntsen, quality isn’t an afterthought—it is the foundation of everything we produce. Survey markers must endure decades in the field under harsh conditions, which is why we start with only the highest-grade raw materials trusted by surveyors, engineers, and agencies nationwide.

Superior Alloys for Lasting Performance

Aluminum 6000 series bars awaiting processing at Berntsen

Our aluminum survey caps are manufactured from 6000 series aluminum bars, cold forged to create high strength, lightweight products. This alloy, composed primarily of magnesium and silicon, offers the ideal balance of strength, corrosion resistance, machinability, and weldability. It is widely used in structural and architectural applications, making it perfect for survey caps that must last as long as the projects they mark.

Orbital forged aluminum caps awaiting stamping

For bronze survey caps, we use only naval bronze. With a composition of roughly 59–62 percent copper, 0.5–1 percent tin, and the remainder zinc, naval bronze is exceptionally durable and resistant to seawater corrosion. That makes it trusted not only for rugged survey applications, but also in marine environments where performance is critical.

Customers who depend on accuracy, compliance, and longevity choose Berntsen because our caps are engineered from the same premium materials used in mission-critical industries.

The Orbital Forging Advantage

High quality metals are only the beginning. Berntsen is the only American manufacturer of survey caps that uses orbital forging, a rare cold forging process that compresses metal into perfectly uniform, incredibly strong one-piece caps.

Unlike other methods that may weld two separate pieces of metal together, orbital forging shapes the entire marker from a single solid bar. This eliminates weak points at weld seams and creates a more durable product designed to withstand decades in the field.

The process also increases the tensile strength and hardness of the material. Unlike casting, orbital forging does not weaken the metal with heat or multiple steps. Instead, the upper die compresses the bar stock with a controlled wobble motion, shaping the metal much like a hand shaping dough. The result is a marker with superior integrity, consistency, and strength that professionals trust for long term reliability.

Smooth bronze survey caps ready for stamping

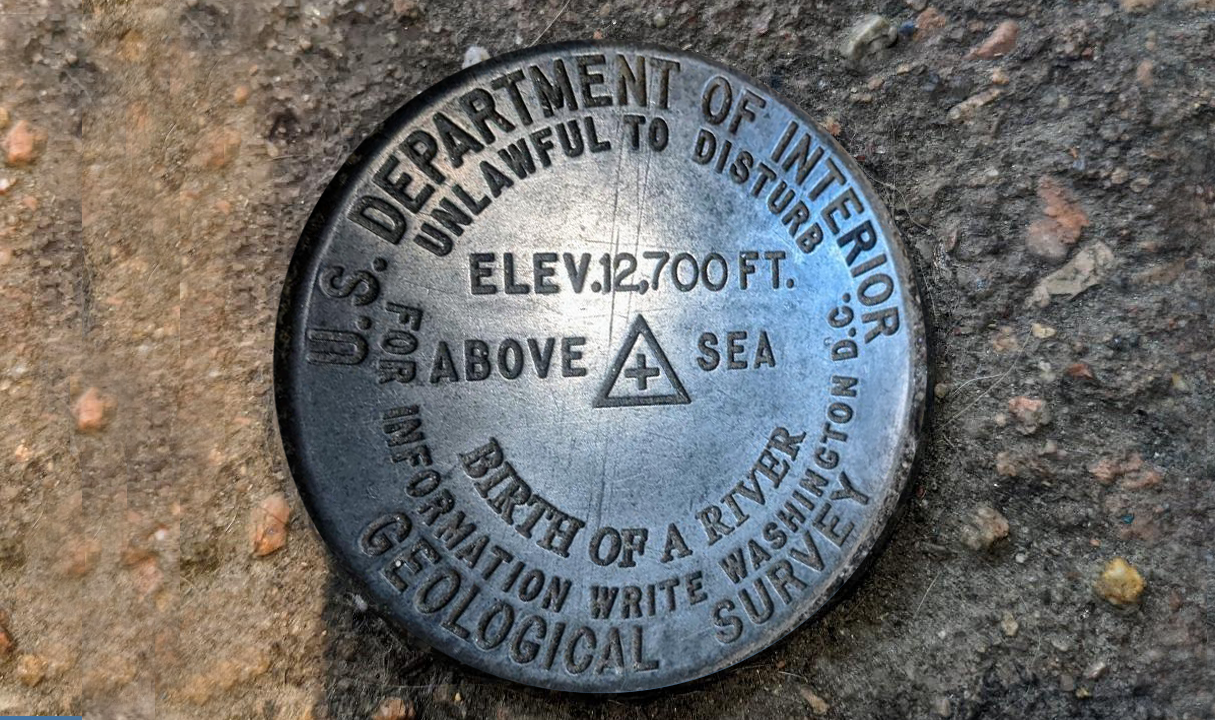

Berntsen marker used by the Department of Interior

Why Customers Choose Berntsen Over Others

An orbital forged cap delivers measurable benefits that traditional cast caps cannot provide.

Stronger – Tensile strength three to four times higher than cast bronze caps, resisting breakage, chipping, and field damage.

Smoother – Surface finish up to ten times better than cast products, resisting corrosion and maintaining a professional appearance.

Faster – One step manufacturing allows Berntsen to deliver orders in half the time of competitors who rely on casting and secondary processes.

Surveyors, engineers, utilities, and public agencies choose Berntsen because these advantages reduce failures, lower replacement costs, speed up project timelines, and ensure their work is marked with the highest standard of quality.

Applications That Demand Berntsen Quality

Berntsen marker placed at Mount McKinley

Berntsen survey caps are trusted in critical projects where accuracy, durability, and accountability matter most.

Land Surveying and Engineering – Permanent markers that withstand decades of exposure and maintain legibility for boundary and control points.

Utilities and Infrastructure – Long life caps that identify underground assets and support compliance requirements without costly replacements.

Transportation and Public Works – Departments of Transportation and municipalities rely on Berntsen caps for reliable, uniform survey monuments that stand the test of time.

Environmental and Marine Projects – Bronze caps that resist seawater and extreme environments, ensuring long term reliability in coastal and wetland applications.

Built in the USA for Surveyors Everywhere

Every Berntsen metal survey marker is made in the USA, a distinction that underscores our commitment to quality, reliability, and supporting the industries we serve. By combining premium alloys with advanced orbital forging, we deliver markers that set the benchmark for strength and durability—ensuring that surveyors, engineers, and agencies can trust their work will stand the test of time. To view Berntsen's extensive metal marking options, go to our survey page here: https://www.berntsen.com/Surveying